The digital edition of the magazine is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing this short registration form.

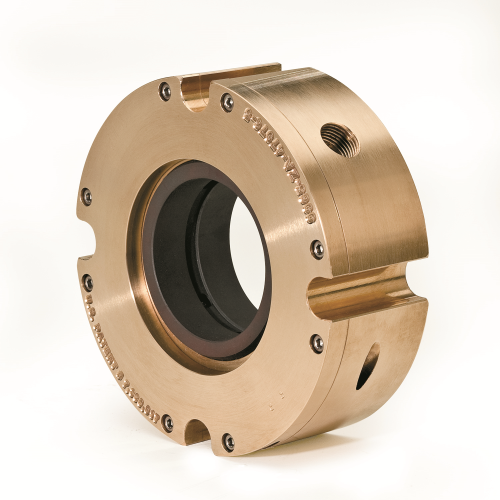

Packing is one of the oldest, if not the oldest, means of sealing a rotating shaft, and continues to be widely used with pumps, agitators, mixers, conveyors and many other products. However, packing is notorious for damaging shafts. In addition, it demands a significant amount of maintenance, which takes up valuable time. Moreover, packing, because it creates heat via friction, requires flushing to remain cool. Flushing can be done with water but, in most cases, the product being sealed (such as light gas oil in refineries) is used. So, the cost of flushing can vary from minimal to substantial.Packing does indeed offer benefits to the user. It is relatively inexpensive, comes in many different materials and is a proven solution. It works particularly well in services where the product is neither dangerous nor valuable, such as vertical pumps in cooling towers. In the end though, packing eventually will leak and will leak sooner if not attended to properly. Packing works because of the pressure asserted by the gland — in essence making it impossible for the product to pass through. However, the product and the shaft eventually will wear the packing down; thus the gland continually must be tightened to maintain the pressure and, consequently, the seal. The packing will leak if not tightened properly and also will fail prematurely if over-tightened. Packing only can be tightened so much before it can’t be tightened any further and must be replaced.Mechanical seals are another option for sealing rotating equipment, and are widely used throughout the process industries. They haven’t been around as long as packing but certainly are a proven alternative. The technology became popular after World War II and has improved over time. Mechanical seals consist of four components (drive mechanism, primary seal, secondary seal and actuator). The key element is the primary seal, which has two seal faces, each made of a different material — one face rotates, while the other remains stationary.Mechanical seals work great on pumps, compressors, reactors and other critical and precise pieces of equipment. However, they tend to be very sensitive to system upsets and the environment in which they are installed. This is due to the very flat and extremely small clearance of the two seal faces. These faces mustn’t touch but must stay exceedingly close. The seal will fail if the faces rub or if they are pulled apart.Other optionsTwo final and relatively new alternatives to packing are air- and gas-purged seals. Such seals provide a clearance seal, meaning no contacting parts are critical to sealing, and thus exhibit minimal wear. They work by maintaining the sealing medium at a higher pressure than that of the equipment being sealed.These seals come with a tremendous upside. They are a permanent sealing solution and don’t need tightening or complex secondary systems. In fact, the only requirement is that the pressure inside the seal is greater than the pressure it’s sealing against. Moreover, the seals are adjustable — for example, you can turn the pressure up or down if there’s a change in the system. Air seals aren’t the answer for all rotating equipment, though. They come with their own shortcomings. For example, the system must be vented to allow the air or gas to escape and not over-pressure the piece of equipment being sealed. In addition, the product being sealed must be compatible with the seal medium (air or gas) being used. These two requirements make it very difficult to use these kinds of seals on pumps because the air or gas will cause cavitation. Air- or gas-purged seals also rely heavily on the tight clearance between the seal and the shaft and, as a result, can fail or become inefficient if that clearance opens up. In addition, because the pressure inside the seal must exceed the product pressure, the air or gas pressure available at a plant may limit their use there.Air-purge seals, like the Air Mizer, typically are used in low-pressure and low-speed applications that have misalignment, high vibration and shaft run-outs. These seals work great in these types of applications, where mechanical seals typically fail. However, they typically don’t do well in high-speed and high-pressure applications.Choose wiselyIn the end, there’s no one-size-fits-all sealing solution for rotating equipment. Mechanical seals always will be needed in high-speed, high-pressure and highly critical applications. However, they require a high level of precision that makes them unsuitable for a large number of services. These other services are where packing normally is used because it doesn’t demand the level of precision and isn’t as delicate as mechanical seals. Air/gas seals are great alternatives to packing for the majority of such services. Not only can they seal the same applications but also they do so with less maintenance, higher mean time between repairs and without damaging equipment.Tom Horner was formerly product manager at Inpro/Seal, Rock Island, Illinois. Neil Hoehle is Inpro/Seal’s global director of technology and he can be contacted at nhoehle@inpro-seal.com.

The digital edition of the magazine is distributed free of charge to readers who meet our qualifying criteria. You can apply to receive your free copy by completing this short registration form.